Ndondomeko yoponyera

Kufotokozera Kwachidule:

Ndondomeko yoponyera ndiyo njira yomwe zinc, mkuwa, aluminiyamu, magnesium, lead, malata ndi aloyi aloyi ndi alloys awo amasungunuka kutentha kwambiri ndikulowetsedwa munkhokwe, kenako kuzirala pansi pamavuto kuti mupeze magawo.

Kutentha kwa ntchito yopanda chitsulo zitsulo kuponyera kumakhala kotsika kwambiri kuposa kuponyera kwazitsulo, ndipo zida zogwiritsira ntchito zoyeserera ndizofunikira ndizosavuta, komanso zazing'ono. Kupanga kuponyera kumatha kupeza mawonekedwe abwino kwambiri komanso kulondola kwenikweni, makamaka koyenera kupanga zazikulu zazing'ono ndi zazing'ono, zomwe zimapereka gawo labwino lothandizira zamagetsi amakono, zida zamagetsi, magalimoto, zida zamankhwala, zida ndi kithen zida. Alloys zosiyanasiyana zazitsulo zimakhala ndi mawonekedwe osiyanasiyana pakuponyera kufa. Gawo lawo locheperako komanso zolemba zochepa ndizosiyana, kutentha kwa malo kosiyanasiyana ndikosiyana, kumaliza kwake kumakhala kosiyana, Chifukwa chake ndibwino kuphatikizira gulu lathu la mainjiniya koyambirira panthawi yopanga kuti tigwiritse ntchito ukatswiri wathu pakupanga.

Pali zinthu zisanu zikuluzikulu ndondomeko zitsulo kufa kuponyera:

1.Die akuponya zakuthupi;

2. Mitundu ya Njira Yoponyera Imfa;

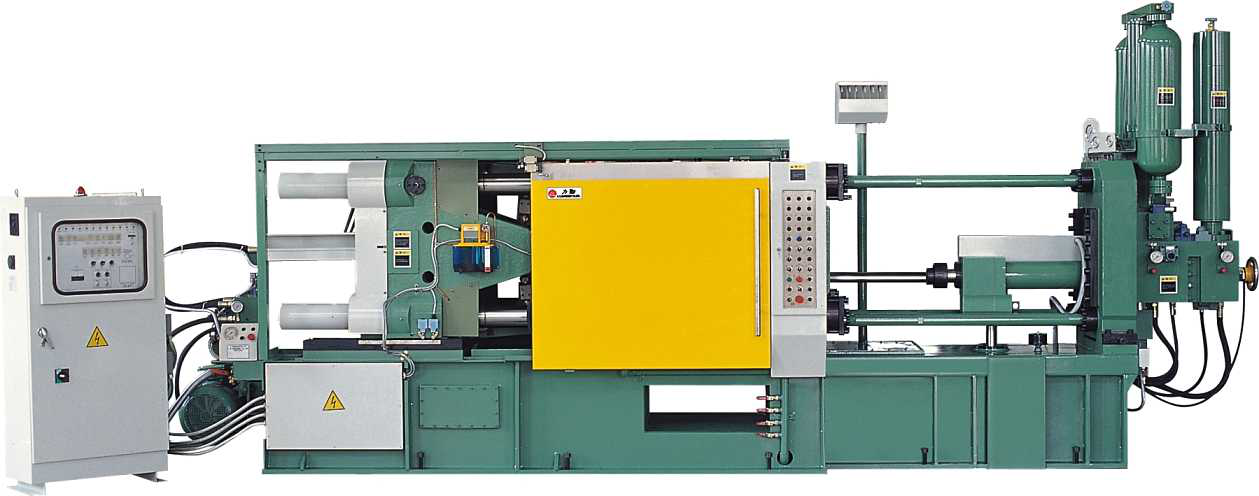

3.Die kuponyera makina;

4.Die kuponyera nkhungu;

5.Post Processing ndi Kutsiriza kwa Die Casting Parts

Zitsulo kufa kuponyera ndondomekondi njira yolumikizira kuthamanga, kuthamanga ndi nthawi pogwiritsa ntchito zinthu zitatu za makina, nkhungu ndi aloyi. Zitsulo otentha ntchito, kuli mavuto ndi khalidwe lalikulu la ndondomeko kufa kuponyera amene ndi osiyana ndi njira zina kuponyera. Anzanu kuponyera ndi njira yapadera kuponyera ndi zochepa ndipo palibe kudula, amene zachitika mofulumira luso lamakono zitsulo processing. Ndi njira yodzaza nkhungu ndi chitsulo chosungunuka pansi pa kuthamanga kwambiri komanso kuthamanga kwambiri, ndikupanga kuponyako ndi crystallization ndikukhazikika pansi pamavuto. Kuthamanga ndi kuthamanga kwambiri ndizofunikira kwambiri pakuponyera kufa. Kupanikizika komwe kumagwiritsidwa ntchito ndimakhumi a megapascals, liwiro lodzaza (liwiro lamkati pachipata) lili pafupifupi 16-80m / s, ndipo nthawi yodzaza yamadzimadzi achitsulo munthumba yayifupi kwambiri, pafupifupi 0.01-0.2s. Zitsulo kufa kuponyera ndi njira yoponyera chitsulo yomwe imadziwika ndi kukakamiza chitsulo chosungunuka ndikukakamizidwa kwambiri kuti chikhale nkhungu. Nkhuni yapakhungu ndi pachimake imapangidwa pogwiritsa ntchito zitsulo zolimba zomwe zakonzedwa mwaluso ndikugwiranso ntchito chimodzimodzi ndi nkhungu ya jekeseni panthawiyi. Kutengera mtundu wachitsulo chomwe akuponyedwa, makina otentha kapena ozizira amagwiritsidwa ntchito.

1.Die akuponya zakuthupiMESTECH imapereka magawo oponyera kufa kwa aloyi wa zinc, aloyi aluminiyamu ndi magnesium alloy. Chifukwa zida zitatuzi ndizomwe zimagwiritsidwa ntchito kwambiri poponya aloyi pakadali pano.

Nthaka aloyi makhalidwe:

--- Mphamvu yayikulu ndi kuuma

--- Wabwino madutsidwe amagetsi

--- Kutentha kwakukulu

--- Zodula zopangira

--- Kulondola kwenikweni ndi kukhazikika

--- Wabwino khoma luso

--- Kutha kuzizira, komwe kumathandizira kujowina

--- Makhalidwe apamwamba kwambiri

--- Kukana kwapadera kwa kutupa - Kukonzanso kwathunthu

Makhalidwe a Aluminiyamu:

- Kutentha kotentha kwambiri

--- Kukana kwapadera kwa dzimbiri

--- Opepuka

--- Mphamvu ndi kuuma kwabwino kwambiri

Kuuma kwabwino komanso kulemera kwake mpaka kulemera kwake

--- Wabwino EMI ndi RFI zoteteza katundu

--- Wabwino matenthedwe madutsidwe

--- Kuchita bwino kwamagetsi

--- Makhalidwe abwino omaliza

--- Kukonzanso kwathunthu

3. Makhalidwe a Magnesium Alloy:

--- Kuchita bwino; magetsi, ndi matenthedwe

--- Kupirira kutentha kwakukulu kogwirira ntchito

--- Kulondola kwenikweni ndi kukhazikika

--- Wowoneka bwino woonda khoma

--- Kukana kwabwino kwachilengedwe

--- Makhalidwe abwino omaliza

--- Kukonzanso kwathunthu

1 Njira Yoponyera Chotentha

Hot-chipinda kufa kuponyera, komwe kumatchedwa gooseneck kuponyera, ndi kotchuka kwambiri munjira ziwiri zomwe zimaponyera. Pochita izi, chipinda champhamvu cha jekeseni chimamizidwa kwathunthu kusamba kwachitsulo chosungunuka. Makina opangira chitsulo a gooseneck amakoka chitsulo chosungunuka mchimbudzi.

Ngakhale kumizidwa molunjika mu bafa yosungunuka kumalola jakisoni wachangu komanso wosavuta, kumathandizanso kutukuka kwa dzimbiri. Chifukwa cha izi, njira yotentha yapa chipinda chofunda ndiyabwino kwambiri pazogwiritsa ntchito zitsulo zomwe zimasungunuka pang'ono komanso kutentha kwambiri. Zitsulo zabwino zachitetezo chamkati chazotentha zimaphatikizira lead, magnesium, zinc ndi mkuwa.

2 Njira Yoponyera Cold-Chamber Die

Njira yozizira yoponya m'chipinda chozizira ndiyofanana kwambiri ndi kuponyera chipinda chotentha. Ndi kapangidwe kamene kamayang'ana pakuchepetsa dzimbiri pamakina m'malo mochita bwino, chitsulo chosungunuka chimangodzipangira- kapena chimadziphatika m'manja mu jakisoni. Izi zimathetsa kufunikira kwakuti jakisoni azimizidwa mu bafa yachitsulo chosungunuka.

Pazinthu zomwe zikuwononga kwambiri pomiza kumiza chipinda chotentha, njira yozizira yachipindacho ikhoza kukhala njira yabwino kwambiri. Izi zikuphatikiza kuponyedwa kwazitsulo zotentha kwambiri, monga zotayidwa ndi aluminiyamu.

3 Njira Yopanikizika Yakufa

Kutsika kotsika kwambiri ndi njira yoyenera kwambiri pazinthu zotayidwa zomwe ndizofanana mozungulira olowera. Mwachitsanzo, magudumu agalimoto amapangidwa kudzera pakuponya pang'ono. Pochita izi, nkhunguyo imakhala pamwamba pazitsulo zosungunuka ndipo imalumikizidwa kudzera pa chubu chokwera. Chipindacho chikapanikizika (nthawi zambiri pakati pa 20 ndi 100kPa), chitsulo chimakokedwa m'mwamba ndikulowamo. Kuchotsedwa kwa odyetsa amtunduwu pazinthu zoponyera kumapereka zokolola zambiri.

4 Njira Yopumulira Yakufa

Zingalowe kuthamanga kuponyera (VPC) ndi njira yatsopano yoponyera yomwe imapereka mphamvu zowonjezereka komanso porosity yochepa. Njirayi ndiyofanana ndi kuponyera kotsika pang'ono, kupatula malo omwe nkhungu amamenyera komanso kusamba kwachitsulo. Chipinda chamiyala chimatha kukhala chopanda kanthu, chomwe chimakakamiza chitsulo chosungunuka muchimbudzi. Kapangidwe kameneka amachepetsa kusokonekera komanso kumachepetsa kuchuluka kwamagesi. Zingalowe kufa kuponyera ndi kopindulitsa makamaka ntchito zoyembekezera pambuyo kuponyera chithandizo kutentha.

5 Njira Yofinya Kufa

Finyani kuponyera idapangidwa ngati yankho lothandiza pakuponyera zitsulo ndi kasakaniza wazitsulo ndi madzi otsika. Pochita izi, chitsulo chosungunula chimadzaza chitseko chotseguka, chomwe chimafinya kutsekera, ndikumakakamiza chitsulo kuti chikhale mbali zoumbirazo. Njira yoponyera imakhala ndi zinthu zowirira kwambiri ndipo ndi njira yothandizirana kuchitira kutentha pambuyo pake. Njirayi imagwirizanitsidwa kwambiri ndi aluminiyamu yosungunuka, ndipo imagwiritsidwa ntchito m'mapulogalamu omwe amafunika kulimbikitsidwa ndi fiber.

6 The theka-Olimba Die kuponyera Njira

Kuponyera kokhazikika, komwe nthawi zina kumatchedwa Thixoforming, ndi njira ina yomwe imapereka porosity yocheperako komanso kuchuluka kwake. Makina amadula chojambulacho kukhala tinthu tating'onoting'ono, kenako nkutenthetsa. Chitsulo chikangofika pakadutsa gawo lolimba pakati pa madzi ndi madzi, zomwe zimapangitsa kuti pakhale mawonekedwe osalala, mkombero wowombera umawukankhira mchikombole, pomwe umauma. Ubwino wa izi ndikulondola bwino. Zitsulo zosapanga dzimbiri monga magnesium alloy ndi aluminium alloy nthawi zambiri zimagwiritsidwa ntchito ndi njira yolimba yolumikizira kufa.

7. Mitundu ya Njira Yoponyera Imfa

Mitundu yonse kufa kuponyera tinapangidwa ndi cholinga chomwecho mu malingaliro-ponyani nkhungu pogwiritsa ntchito chitsulo chosungunuka. Kutengera mtundu wa chitsulo chosungunuka, gawo lina la masamu ndi kukula kwake, njira zosiyanasiyana zoponyera zimatha kupereka zotsatira zabwino koposa njira zina. Mitundu iwiri ikuluikulu yazakudya zimaponyera chipinda chocheperako komanso chipinda chozizira. Kusiyanasiyana kwamitundu iwiriyi yophatikizira anthu ndi monga:

Low-anzanu kufa kuponyera

Zingalowe kufa kuponyera

Finyani kufa kuponyera

Theka-olimba kufa kuponyera

1 Hot Press chipinda kufa kuponyera makina

Malinga ndi kapangidwe kake ndi chipinda, chitha kugawidwa m'mitundu yopingasa komanso yowongoka. Mbiya yachitsulo chosungunuka imamangiriridwa pamakina ndi chipinda chowotcha chotentha, ndipo makina a pisitoni azitsulo zamagetsi olowa mu nkhungu amaikidwa mu mbiya. Makina ena otentha omwe amaponyedwa amagwiritsa ntchito mpweya wothinikizika kuti alowe mwachindunji pachitsulo chosakanizidwa ndi hayidiroliki muchikombole chopanda pisitoni.

Hot chipinda kufa kuponyera makina

Kutentha kukanikiza chipinda kufa makina oponyera amagwiritsidwa ntchito kwambiri popanga aloyi woponya ndi malo otsika pang'ono, monga zinc, Magnesium ndi malata.

2 Cold pressure chipinda die kuponyera makina

Kusungunula chitsulo kunja kwa makina ndikuwonjezeranso chitsulo cham'madzi mchipinda chopondera ndi supuni chitha kugawidwa pamakina ozizira otentha ndikutulutsa makina ozizira ozizira molingana ndi momwe pisitoni yamavuto imayendera.

Chitsulo chamadzimadzi chimachotsedwa m'ng'anjo yazitali mozungulira chojambula chojambulira chikufa ndikuthira mchipinda chopondera. Chitsulocho chimakanikizidwa ndi nkhungu ndi nkhungu, ndipo chitsulo chotsalacho chimakankhidwa ndi pisitoni ina.

Cold chipinda kufa kuponyera makina

Cold chipinda kufa kuponyera makina

The yopingasa ozizira chipinda kufa kuponyera makina ndi chimodzimodzi ndi ofukula, koma kayendedwe pisitoni ndi yopingasa. Makina ambiri amakono oponyera amapingasa. Makina opangira zida zozizira amatha kufa amatayira zitsulo zosungunuka kapena zitsulo zosavuta, monga aluminiyamu, alloys zamkuwa, ndi zina zambiri.

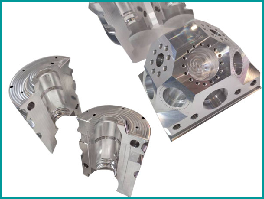

3.Die kuponyera makina.

Makina opangira makina amagwiritsira ntchito makina oponyera. Pamafunikanso mitundu iwiri ya otentha kukanikiza chipinda kufa kuponyera makina ndi ozizira kukanikiza chipinda kufa kuponyera makina. Ozizira kukanikiza chipinda kufa kuponyera makina lagawidwa mitundu iwiri: molunjika ndi yopingasa. Chitsulo chosungunuka chimalowetsedwa mu nkhungu ndimakina oponyera pansi pochita kukakamizidwa kuzirala ndikupanga, ndipo zolimba zazitsulo zimatha kupezeka chikombocho chitatsegulidwa.

Hot chipinda kufa kuponyera makina

Cold chipinda kufa kuponyera makina

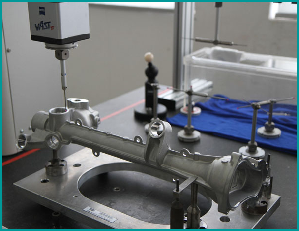

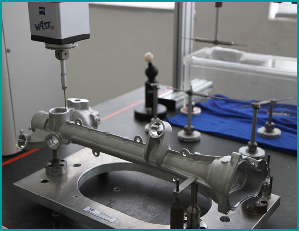

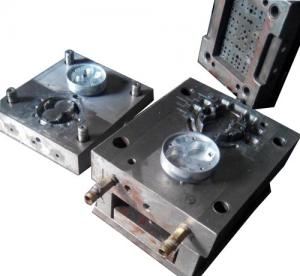

4.Die kuponyera nkhungu

Amatha kuumba zosiyanasiyana, zikhalidwe ntchito kufa kufa kuponyera kufa ndi m'malo nkhanza. Kufa kumapangidwira ndikupanga chitsulo chosungunuka chodzaza ndi nkhungu pansi pa kuthamanga kwambiri komanso kuthamanga kwambiri, ndikulumikizana ndi chitsulo chotentha mobwerezabwereza panthawi yogwira ntchito. Choncho, kufa kuponyera nkhungu kumafunika kukhala ndi matenthedwe otopa kukana, matenthedwe otentha komanso kuvala kukana, kukana dzimbiri, kulimba mtima, kuuma kofiira, kuwononga bwino ndi zina zambiri. Choncho, pamwamba chithandizo mankhwala a kufa kuponyera chikufa amafuna luso mkulu.

Kufa kuponyera nkhungu

5.Post Processing ndi Kutsiriza kwa Die Casting Parts

Timapereka mautumiki ambiri okonzanso ndi kutsiriza magawo omwalira kuchokera kwa omwe tidawasankha:

Mapulogalamu

CNC Machining - ofukula, yopingasa, kutembenukira, 5-olamulira

Wokutira ufa

Kupaka Zamadzimadzi

EMI - RFI Kuteteza

Kuyala - chrome, mkuwa, zinc, faifi tambala, malata, golide

Anodizing, Kukutira kwamagetsi, Chromating / Kusagwirizana

Chithandizo Cha Kutentha, Passivation, Tumbling

Zojambula

Njira Zojambula M'nyumba

Kuwunika Silika

Kusindikiza Pad

Kuphulika kwa mkanda

Kuwala Mawotchi Assembly, kuphatikizapo sitadi ndi helicoil oyika, O-mphete, gasket

Laser kudula ndi mochita

Etching

Kupaka Magetsi & Kuwunika Silika