Zokuthandizani pazinthu zenizeni za pulasitiki kapangidwe kake

Kufotokozera Kwachidule:

Mwatsatanetsatane mbali pulasitiki kapangidwe ndi jekeseni akamaumba iyenera kuyamba pazinthu zopangira, kapangidwe kazinthu, kapangidwe kake ndi kukonza, makina akamaumba jekeseni, magwiridwe antchito komanso malo abwino opanga.

Ndikukula kwa mafakitale amakono, pali zinthu zabwino kwambiri za pulasitiki. Nthawi yomweyo, zopangidwa ndi pulasitiki zimagwiritsidwanso ntchito m'mafakitale osiyanasiyana. Makamaka, amagwiritsa ntchito pulasitiki kwambiri. Tsopano tiyeni tigawane nanu maupangiri amakapangidwe apangidwe ndi pulasitiki.

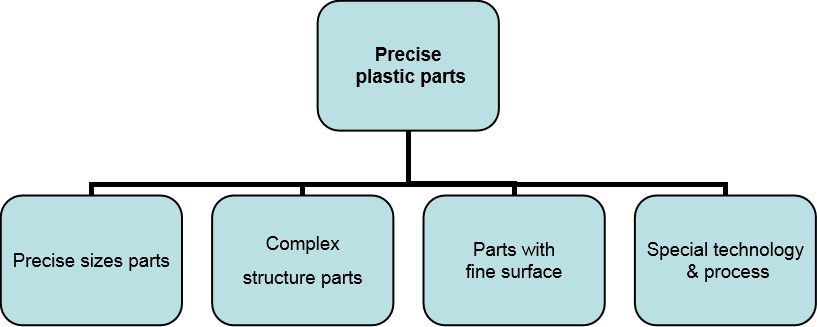

Gulu lachindunji

mbali pulasitiki:

1. Mapangidwe apadera a pulasitiki

(1) Mitundu yoyerekeza yazinthu zenizeni za pulasitiki

A. Mbali zowoneka bwino kwambiri, monga: magiya oyendetsa galimoto, magiya anyongolotsi, zomangira, mayendedwe. Magawo enieniwa amagwiritsidwa ntchito pamakina oyendetsera makina (monga osindikiza, makamera, zotsukira zodziwikiratu, maloboti, zida zamagetsi, ma UAV ang'ono, ndi zina zambiri). Amafuna kulumikizana bwino, kuyenda mosadukiza, kukhazikika komanso kopanda phokoso.

B. magawo olimba:

Kawirikawiri, khoma la magawo apulasitiki limakhala lochepera 1.00mm, lomwe ndi laling'ono. Zida zazing'ono zingapangitse kukula kwa malonda kukhala kocheperako. Koma ziwalo zapulasitiki zopanda zingwe sizingadzazidwe chifukwa cha kuzizirira mwachangu komanso kolimba. Ndipo ziwalo zopyapyala-zolimba sizingathe kupirira mphamvu yaimfa ndikuphwanya mphako. Chifukwa chake, kapangidwe ka magawo okhala ndi mipanda yopyapyala ayenera kusankha zida zokhala ndi makina abwino. Ndi mamangidwe wololera, monga yunifolomu khoma makulidwe, mbali sangakhale kwambiri khoma. Kufa kwambiri, ngodya yayikulu. Kwa magawo ena owonda kwambiri, makina opanga jekeseni wothamanga amafunika.

C. Zida zopangira:

Zipangizo zamagetsi zimafunikira magwiridwe antchito abwino / kupititsa patsogolo kuwala, komanso kukhazikika kwamphamvu komanso kukana. Mwachitsanzo, kupindika kwa magalasi a concave ndi ma convex omwe amagwiritsidwa ntchito pama projekiti kumafuna kulondola komanso kukhazikika. Pulasitiki wapamwamba wowonekera ngati PMMA amafunika. Nthawi yomweyo, zida zina zowunikira zimafunikiranso kupanga mizere ina pamwamba pazigawozo kuti zivomereze kuwala kapena kuwala kapena kuchotsa kunyezimira.

D. Malo owala kwambiri:

Mbali zowala kwambiri zimaphatikizapo mbali zowoneka bwino, komanso mbali zina zomwe zimafunikira kumapeto kwa galasi. Zida zamtunduwu zimagwiritsidwa ntchito kwambiri pazinthu zamagetsi zamagetsi, monga zipolopolo zam'manja. Kapangidwe kazinthu zamtunduwu ziyenera kulingalira za zinthu zapulasitiki zokhala ndi fluidity, kapangidwe ka makulidwe ndi ukadaulo wakufa.

E. mbali pulasitiki madzi

Zinthu zambiri zamagetsi zamagetsi ndi zamagetsi zimafunikira umboni wamadzi, monga magalasi / maulonda / madzi ankhondo, zida zakunja ndi zida zamadzi. Njira zazikulu zotsekera madzi ndizisindikizo zobisika kunja kwa malonda, monga makiyi otsekedwa, ma jacks otsekedwa, kusindikiza mabowo, ma ultrasonic welding, ndi zina zambiri.

F.IMD / IML (mu-nkhungu-kukongoletsa, mu-nkhungu-chizindikiro)

Izi ndikuyika filimu ya PET mu jekeseni wa jekeseni ndikuphatikizira magawo a jekeseni muukadaulo wonse wogwiritsa ntchito, womwe ungadziphatike mwamphamvu kuzinthu za pulasitiki. Zogulitsa za IMD / IML zimawonetsera: kumveka bwino, stereoscopic, sizimatha; kuwonekera kwamagalasi azenera mpaka 92%; kuvala zosagwira ndi zikande zosagwira pamwamba pa moyo wautali wautumiki; Buoyancy ya mankhwala kofunika pa akamaumba jekeseni, moyo kiyi angafikire nthawi zoposa 1 miliyoni.

Wopanda khoma pulasitiki gawo

Gulu la pulasitiki la IMD / IML

Mbali zenizeni za pulasitiki

Gawo loyang'ana / chivundikiro chowonekera

Mlanduwu wapawiri wa jekeseni

Mlanduwu wazinthu zamagetsi

Nyumba zokhala zovuta

(2) .Malangizo a mapangidwe apadera apulasitiki

A. yunifolomu khoma makulidwe Mu jekeseni akamaumba, pulasitiki ili m'malo amadzimadzi kwakanthawi kochepa kwambiri, ndipo kufanana kwa makulidwe amakoma azigawo kumakhudza kwambiri kuthamanga kwa mathamangidwe ndikuwonekera kwa pulasitiki. Kukula kwa magawo kumasintha kwambiri, komwe kumabweretsa zovuta zambiri monga kudzazidwa ndi kusakhutira, kuchepa, kuchepa, ma weld weld, kupsinjika kwakanthawi kochepa komanso zina zotere, chifukwa chake khoma lolimba lazipulasitiki zenizeni liyenera kukhala lofanana zotheka pakupanga. Kusintha kwamakulidwe sikuyenera kukhala kwakukulu kwambiri, ndipo kutsetsereka kapena kusintha kwa arc kuyenera kupangidwa pakusintha.

B. samalani kulumikizana pakati pazigawo ndikupanga kukula koyenera koyenera. Pofuna kuwonetsetsa kuti kusinthana pakati pamasinthasintha, nthawi zambiri timapereka zofunikira kuti zigawo zilizonse zizilondola. Koma kwa magawo apulasitiki, ili ndi kusinthasintha kwina komanso kusinthasintha. Nthawi zina, bola kapangidwe kake ndi koyenera, kupatuka kumakonzedwa ndi kulumikizana pakati pazigawo, kuti muyeso wolondola ukhale womasuka moyenera kuti muchepetse zovuta zopanga. Digiri.

C. Kusankha zakuthupi Pali mitundu yambiri yazida zamapulasitiki, ndipo magwiridwe antchito amasiyanasiyana. Pazipangizo zenizeni za pulasitiki, zida zokhala ndi zocheperako / mapindikidwe ang'ono / mawonekedwe okhazikika / nyengo yabwino kukana amasankhidwa malinga ndi zofunikira pakugwiritsa ntchito. (a) ABS / PC yokhala ndi shrinkage yotsika imagwiritsidwa ntchito m'malo mwa PP ndi shrinkage yayikulu, ndi PVC / HDPE / LDPE yotsika pang'ono. ABS + GF imagwiritsidwa ntchito m'malo mwa ABS.PC + GF ndi PC. (b) Sankhani PA66 + GF kapena PA6 + GF m'malo mwa POM kapena PA66 ndi PA6.

D. mokwanira kuganizira ndondomeko akamaumba.

(a) Pazipolopolo wamba, bokosi kapena zimbale, ndibwino kupanga microstrip arc pamwamba ndikulimbitsa mkati kupewa kupindika.

(b) Pazinthu zopyapyala kwambiri, makulidwe ake azikhala ofanana, ndipo zamkati siziyenera kukhala ndi nthiti zokulitsa kapena zomanga. Ndi bwino kugwiritsa ntchito makina othamanga kwambiri a jekeseni.

(c) Mphuno yotentha kapena nkhungu zothamanga zimagwiritsidwa ntchito pamagulu akulu kuti azitenga nthawi yodzaza ndikuchepetsa kupsinjika ndi kusintha.

(d) pazigawo ziwiri zopangidwa ndi zinthu ziwiri, jakisoni wamitundu iwiri m'malo mwa jekeseni wa guluu amatengedwa.

(e) jekeseni wowongoka umalimbikitsidwa pamagawo okhala ndizitsulo zazing'ono.

E. Ali ndi malo osinthira. Pakapangidwe kazinthu zenizeni za pulasitiki, ndikofunikira kuwunika zolakwika zomwe zingachitike mtsogolo.

(3) Kutsimikizira kwamapangidwe

Ma jekeseni a jekeseni amakhala ndi mtengo wokwera, nthawi yayitali komanso kukwera mtengo kosintha, chifukwa chakumaliza kwa kapangidwe kake, ndikofunikira kupanga zitsanzo zakuthupi kuti zitsimikizire kapangidwe kake, kuti muwone kulingalira kwa magawo amapangidwe azinthu, kupeza mavuto ndikuwongolera mopangiratu.

Kapangidwe kazitsimikizidwe kathupi kamakwaniritsidwa makamaka pakupanga mtundu wachitsanzo. Pali mitundu iwiri ya zinachitika kupanga: CNC processing ndi 3D yosindikiza.

Kugwiritsa ntchito zotsimikizira zakuthupi kumafunikira chidwi pazinthu izi:

Ndalama zopangira zojambula za A.CNC nthawi zambiri zimakhala zapamwamba kuposa kusindikiza kwa 3D. Kwa magawo akulu, mtengo wa processing wa CNC ndiwotsika.

Zida ndi zida zamakina kapena chithandizo chapamwamba ndi zofunikira pamisonkhano, kukonza kwa CNC ndikulimbikitsidwa, kuti pakhale mphamvu yabwino yama makina. Kwa magawo ang'onoang'ono ndi mphamvu zochepa, kusindikiza kwa 3-D kumagwiritsidwa ntchito. Kusindikiza kwa 3-D ndikosavuta, ndipo kumakhala kotchipa kwambiri kumagawo ang'onoang'ono.

B. Ma prototypes amatha kutsimikizira kusonkhana pakati pa magawo, kuwunika zolakwika ndi kapangidwe kake, ndikuwongolera kukonza kwamapangidwe. Komabe, zinachitika sizingathe kuwonetsa zofunikira zaumisiri pakupanga nkhungu, monga kuwumba koyilo / shrinkage / deformation / fusion line ndi zina zotero

2. enieni pulasitiki mbali akamaumba

(1) kapangidwe ka pulasitiki (kapangidwe ka nkhungu) Zipangizo zapamwamba kwambiri ndizofunikira pakupanga magawo enieni. Mfundo zotsatirazi zikuyenera kutsatira.

A. sankhani molondola kuchuluka kwa zinthu zapulasitiki. Wololera malo mbali mu nkhungu.

B. nkhungu pachimake zakuthupi zidzasankhidwa ngati zinthu zachitsulo ndi kukhazikika / kuvala kukana / kukana kwazitsulo.

C. Njira yodyetsera nkhungu imagwiritsa ntchito Tsui wotentha kapena wothamanga wotentha momwe angathere, kotero kuti magawo a gawo lililonse la kufanana kwa kutentha, amachepetsa kupindika.

D. nkhungu iyenera kukhala ndi dongosolo labwino lozizira kuti zitsimikizire kuti ziwalo zakhazikika mofanana m'nthawi yochepa.

E. nkhungu iyenera kukhala ndi loko logwirizira ndi zida zina zoyikapo.

F. moyenera ikani njira yochotsera ejector makina, kuti mphamvu yochotsera magawo ikhale yunifolomu osati yopunduka.

Kupanga nkhungu ndi kusanthula chida chofunikira (moldfow): Pogwiritsa ntchito pulogalamu yoyeserera ya jekeseni kutsanzira kutengera momwe jekeseni imapangira magawo osiyanasiyana, pezani zolakwika pakapangidwe kazinthu ndi kapangidwe ka nkhungu pasadakhale, kuwongolera ndikuwongolera, ndikupewa Zolakwitsa zazikulu pakupanga nkhungu kwambiri, zomwe zitha kutsimikizira kuti nkhunguyo ndiyabwino ndikuchepetsa mtengo pambuyo pake.

(2) kutsimikizira nkhungu.

Mtengo wa nkhungu wosavuta ndi wotsika kwambiri poyerekeza ndi wopanga nkhungu. Pazipangizo zenizeni za jekeseni, ndikofunikira kupanga nkhungu yosavuta kutsimikizira kapangidwe kake musanapangidwe ndi nkhungu, kuti mupeze magawo owongolera kapangidwe ka nkhungu ndikuwonetsetsa kuti nkhungu ipambana.

(3) nkhungu processing

Amatha kuumba apamwamba ayenera makina ndi zotsatirazi makina mkulu yeniyeni.

A. mkulu yeniyeni CNC makina chida

B. makina owala galasi

C. kudula waya pang'onopang'ono

D. kutentha komwe kumagwira ntchito nthawi zonse

E. zida zofunikira zoyesera. Komanso, processing nkhungu ayenera kutsatira ndondomeko okhwima ndi kudalira anthu ogwira ntchito apamwamba ntchito.

(4) kusankha makina opangira jekeseni

Zipangizo jekeseni akamaumba mbali yeniyeni pulasitiki.

A. ayenera kugwiritsa ntchito yeniyeni makina jekeseni akamaumba ndi zaka zosaposa 5 zaka moyo utumiki.

B. malo okhala fakitale ndi oyera komanso aukhondo.

C. pazigawo zochepa kwambiri, payenera kukhala makina othamanga kwambiri.

D. magawo awiri kapena magawo osalowa madzi ayenera kukhala ndi makina awiri owumba jekeseni wamitundu.

F. chitsimikizo chamakhalidwe

(5) kulongedza zigawo zenizeni za pulasitiki

Kuyika bwino ndikofunikira kuti muteteze zokopa, zolakwika, fumbi poyendetsa, kusungira magawo apulasitiki enieni.

A. mbali zazikulu zonyezimira ziyenera kujambulidwa ndi kanema woteteza.

B. Zida zolimba zazing'ono ziyenera kukulungidwa m'matumba apadera kapena thovu, kapena kupatulidwa ndi mpeni wamapepala kuti musavutike.

C. Magawo omwe amayenera kunyamulidwa pamtunda wautali sayenera kuyikidwa momasuka m'makatoni. Makatoni angapo amayenera kulumikizidwa pamodzi ndimatumba ndi alonda.

Kampani ya Mestech ili ndi makina ndi zida zopangira nkhungu zopangira pulasitiki komanso kupanga jekeseni. Tikukhulupirira kukuthandizani kupanga nkhungu ndi ntchito zopanga magawo enieni apulasitiki.